Transfer Die Technology

Transfer tooling for precision deep-draw round shaped stamping products.

Accuracy for Inside diameter of motor housing is critical to its motor performance. Numasho thinks machining made parts as a rival and tries to make them better than machining made with our profound work. Recently, both inside and outside of motor housing require severe tolerance. Numasho has challenged by using combination of material deduction and increasing original material thickness and sticking material to make special motor housing.

Tooling die for producing SUS products

Usually, small SUS parts are produced in high volume mass production. They require stable and efficient production in meeting customer's satisfaction. We install customer's press machine to our factory and have pre-production as many as customer's demand. Numasho promises installing all the machinery to customer's factory. Our transfer system can start mass production right away.

Robot line tooling for manufacturing special pipe

Not only making round draw parts, but also our tooling does cutting, piercing, edge forming, shrinking and etc. Piercing ¦Õ1.0mm holes into 1.8mm thickness (Material = KPM250) at corner of bending pipe. These pierced pipes have been produced 800,000pcs/month with our tooling. Responding customer's needs develop our technology and new idea (inspiration) to come up with.

Others

Numasho's deep drawing parts are developed with customer's need day by day. For cost deduction and parts performance, we have made variety of press products such as side wall of product squeezed to be 30% of its original thickness and keep its original material no less than 5% deduction. Numasho as a tooling maker tries to overcome plasticity transformation limit for development of part performance and its productivity.

Click |

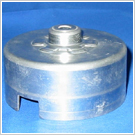

Use

Automobile

Part name

EPS bracket

Size

¦Õ82mm¡ß92mm

Type

Transfer tooling

No. of stage

11

Press spec.

400 ton

|

| I/D milling-less. High Precision Bracket.

I/D¦Õ80¡¢¦Õ82 its tolerance 40um with CPK¡å1.33 |

|

Click

Layout |

Use

Automobile

Part name

Case

Size

¦Õ50mm¡ß40mm

Type

Transfer tooling

No. of stage

9

Press spec.

200 ton

|

| Avoid material slant by parts layout |

|

Click

Layout |

Use

Automobile

Part name

Yoke

Size

¦Õ80mm¡ß100mm

Type

Transfer tooling

No. of stage

9

Press spec.

500 ton

|

| This transfer tooling is shipped out to other countries |

|

Click

Layout |

Use

Appliance

Part name

Bracket A

Size

¦Õ90mm¡ß48mm

Type

Transfer tooling

No. of stage

8

Press spec.

250 ton

|

| Manufacturing in our factory. Care for noise when it's rotated. |

|

Back to Top

Click |

Use

ABS device

Part name

NC SLEEVE

Size

¦Õ7mm¡ß20mm

Type

Transfer tooling

No. of stage

11

Press spec.

45 ton

|

| I/D and O/D total tolerance 50um. Material deduction less than13%. SPM80 |

|

Click

Layout |

Use

Construction

Part name

Door knob

Size

¦Õ52mm¡ß60mm

Type

Transfer tooling

No. of stage

18

Press spec.

200 ton ¡Ü 110 ton + 200 ton

|

| Use hydraulic pressure method. One piece product. |

|

Click |

Use

Appliance

Part name

Electrical gun

Size

¦Õ12mm¡ß20mm

Type

Transfer tooling

No. of stage

12

Press spec.

45 ton

|

| Laser beam run through the upper piercing. |

|

Click

Layout |

Use

Automobile

Part name

Sensor cup

Size

¦Õ40mm¡ß18mm

Type

Transfer tooling

No. of stage

15 + 3manual presses

Press spec.

300 ton

|

| I/D finish is critical. Take 3 processes to finish I/D nice and smooth. |

|

Back to Top

Click |

Use

Automobile safety device

Part name

Pipe

Size

¦Õ20mm¡ß200mm

Type

Automatic robot line tooling

No. of stage

6 (L & R)

Press spec.

6-60 ton press machines

|

¦Õ1.0 piercing hole into 1.8mm thickness. Stand up 800k/month mass production.

Back to Top

Click

Layout |

Use

ABS device

Part name

Cover

Size

¦Õ17mm¡ß25mm

Type

Transfer tooling

No. of stage

9

Press spec.

110 ton

|

| Material thickness on top is 2.3mm( its original), squeeze side wall 0.75mm. SPM45 |

|

|

Click

Layout |

Use

Automobile

Part name

Filer case

Size

¦Õ65mm¡ß63mm

Type

Transfer tooling

No. of stage

6

Press spec.

250 ton

|

| Our most repetition sales of transfer tooling.

Rationalized transfer tooling for efficient production. |

|

Click |

Use

Home accessory

Part name

Oil can top

Size

¦Õ80mm¡ß53mm

Type

Transfer tooling

No. of stage

7

Press spec.

110 ton |

| Required good finish on the surface. Fitting other parts with severe tolerance. |

|